Products

-

Aluminum die cast base and cover of ODU enclosure

High Pressure Die Casting part –

Aluminum die casting enclosure cover

Industry: 5G Telecommunications – Base station units/Outdoor components

Raw material: Aluminum alloy EN AC-44300

Average weight: 0.5-8.0kg

Powder coating : conversion coating and white powder coating

Small defects of coating

The parts used for outdoor communication equipments

-

Aluminum machined Robot arm part with glossy surface

Description of metal component:

CNC Machining/Milling aluminum accessories for Robot

Industries: CNC Machining/Mechnical/Electronics

CNC materials: AL6061

Part weight: 0.5~1.5 KG

Secondary process: CNC machining& tapping

Place of Origin: Guangdong ,China

Export to USA/Canada/Europe

-

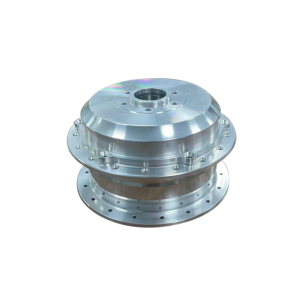

OEM Precision Metal Parts for Customized Aluminium Alloy Bushing

Description of CNC metal component:

Precision CNC machining aluminum bushing for Industry parts

Industries: Rapid Prototyping Service/Mechnical/Electronics

CNC materials: AL6061

Part weight: 0.5~2.5 KG

Secondary process: CNC machining, Polishing

Export to USA/Canada

-

Aluminum bushing by CNC milling with good quality

Description of metal component:

Precision CNC machining aluminum bushing for Industry parts

Industries: CNC Machining/Mechnical/Electronics

CNC materials: AL6061

Part weight: 0.5~1 KG

Secondary process: CNC machining, Polishing

Export to USA/Canada

-

CNC Machining Aluminum Fan Blade with High Quality

Description of metal component:

CNC Machining/Milling aluminum parts for industrial

Industries: CNC Machining/Mechnical/Electronics

CNC materials: AL6061

Part weight: 1.5KG

Secondary process: CNC machining

Export to USA/Canada

-

Die Casting Aluminum Base of PTC used for Electric Vehicle

Product Name: Aluminum casting base of PTC

Industry: Automobile/Gasoline vehicles/Electric vehicles

Die Casting material: ADC12

Production output: 200,000 pcs/year

Die casting material we normally use: A380,ADC12,A356, 44300,46000

Mold material: H13, 3cr2w8v, SKD61, 8407

-

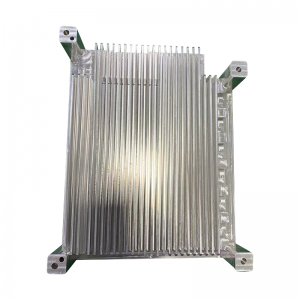

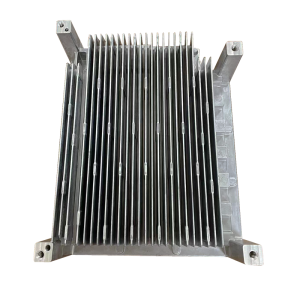

CNC Machining Heat Sink Cover of Electric Vehicle

Description of component:

CNC Machining/Milling Heat Sink Cover of Electric Vehicle

Industries: Electric vehicle/Coil driver system/Automobile

CNC materials: AL6061

Part weight: 3.1KG

Secondary process: CNC machining

Export to USA/Canada

-

Die Casting Aluminum Housing of PTC used for Electric Vehicle

Product Name: Aluminum casting housing of PTC

Industry: Automobile/Gasoline vehicles/Electric vehicles

Die Casting material: ADC12

Production output: 200,000 pcs/year

Die casting material we normally use: A380,ADC12,A356, 44300,46000

Mold material: H13, 3cr2w8v, SKD61, 8407

-

Aluminum Die Casted Heat Sink for Traction Motor Controller of Electric Vehicle

Part details:

Die Casting Molded Heat Sink Enclosure

Industries: Electric vehicle/Coil driver system/Automotive/

Raw casting materials: ADC1(A413)/ADC14

Part weight: 3.1KG

Secondary process : CNC machining +Degreasing

Main Market: USA/Canada/UK

-

Aluminum casting base and cover for 5G outdoor microwave radio product

Item: Aluminum High Pressure Die Casting –ODU Enclosure Base and Cover

Industry: Telecommunication- wireless microwave networks

Casting material: EN AC-44300

Average weight: 1.23kg & 1.18kg High porosity and mechanical strength requirements.

Tolerance: +/-0.05 MM

Die Casting Machine: From 400T to 1650T

Die Casting Mold Materials : 8407, 2344 ,H13 ,SKD61etc.

Mold Life Time : About 80,000 shots.

Export country : USA/Canada

-

Die cast aluminum housing for outdoor microwave enclosure

High Pressure Aluminum Die Casting part – Aluminum die casting housing

Industry: 5G Telecommunication – Base station units/ODU components/outdoor microwave products

Raw material: Aluminum alloy EN AC-44300

Average weight: 0.5-8.0kg

Powder coating : conversion coating and white powder coating

Small defects of coating

The parts used for outdoor communication equipments

-

Die casting heatsink housing of wireless broadband product

Product details:

Aluminum casting heatsink housing of wireless broadband product

Applications: Telecommunications 4G and 5G,packet microwave radio systems products,wireless products,outdoor microwave radio products etc.

Casting materials: Aluminum alloy ADC 12/A380/A356/ADC14/ADC1

Average weight: 0.5-8.0kg

Size: small-medium sized parts

Process: Die casting mold- die casting production-burrs remove-degreasing-packing