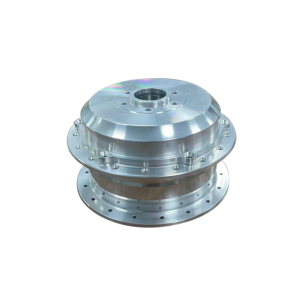

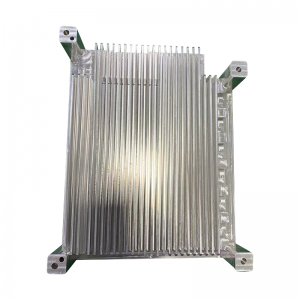

Precision CNC Machined Aluminum Left and Right Junction shell for Extender Chassis

Specifications

Key Specifications

Application used: Electronics/Mechnical/Industrial

Raw CNC materials: Aluminum/Brass/Stainless steel AISI316,AISI304/Copper...

Process: CNC machining& tapping, drilling,turning

Part Features:

Precise CNC machining, 3 Axis and 5 Axis CNC Machining

Low volume for production

Glossy surface after machining

Fast Delivery by UPS or FedEx,DHL.

Typical CNC Parts include:

Housings and Enclosures

Brackets and covers

Chassis , gears and bearings

Heatsink covers, junction housings

Production process

CNC Programming

CNC turning & machining

Deburring

Cleaning

100% Inspection

Package

Surface finish

Polishing /sand blasting /chrome plating /electrophoresis /powder coating /anodizing .

Packaging

Carton/plywood box/plywood pallet, customized packaging solution is also available.

Kingrun Advantage

●Use the latest CNC technology to manufacture high-precision machined parts.

● Possesses 130 sets of 3-axis and 4-axis, 5-axis CNC machines.

● CNC lathing, milling, drilling and tapping, etc. capabilities.

● Equipped with a processing center that automatically handles small batches and large batches.

● The standard tolerance of components is +/- 0.05mm, and tighter tolerances can be specified as well while pricing and delivery are to be affected.

● With the assistance of in-house precise measuring and testing equipment (CMM, Spectrometer, etc.) we can check all incoming materials and parts to meet required specifications.

● Provide FAI report, material data sheet, PPAP three-level document report, 8D report, corrective and preventive action report;

● Have obtained ISO 9001, IATF16949 and ISO14001 certifications and strictly implement in inner management.

We provide the OEM or ODM service for customer and if you have any request, please contact us info@kingruncastings.com.