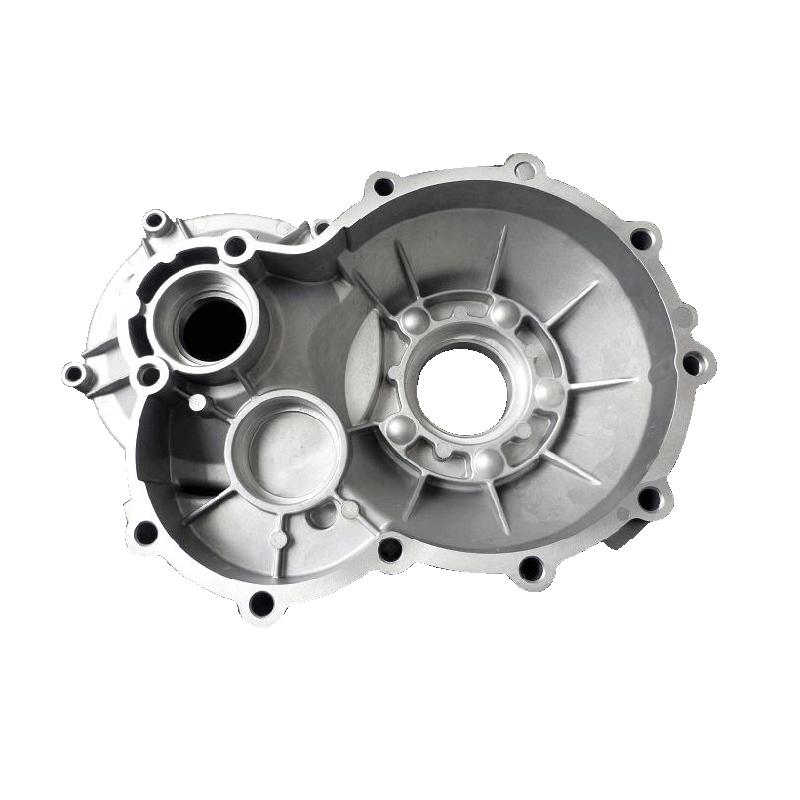

The precision and quality are essential for the smooth functioning of various mechanical systems. One crucial component in the transmission system is the aluminum casting gear box cover. In this blog, we will explore the intricate process of producing high precision aluminum die casting parts, from the initial casting to the final finishing touches.

High Pressure Die Casting:

To begin the process, high-pressure die casting is employed to shape the aluminum alloy into the desired gear box cover. This method involves injecting molten aluminum into a steel mold under high pressure, ensuring accurate replication of the mold design. The result is a robust and precise casting that exhibits excellent mechanical properties.

Trimming and Deburring:

After the casting process, the gear box cover undergoes trimming and deburring. Trimming involves removing the excess material around the edges of the casting to achieve the desired shape and size. Deburring, on the other hand, involves eliminating any rough edges or burrs that may have formed during the casting process. These two steps result in a clean and refined gear box cover ready for further refinements.

Shot Blasting:

Shot blasting is a crucial step in the manufacturing process, as it eliminates any remaining impurities from the surface of the gear box cover. This method involves propelling small metal particles at high speed onto the surface, effectively removing any dirt, scale, or oxidation that might affect the final appearance and functionality of the part. Shot blasting ensures a smooth and pristine surface, ready for the next stage.

Surface Polishing:

To enhance the aesthetics and durability of the gear box cover, surface polishing is employed. This process involves grinding and buffing the surface using abrasive materials and compounds. The goal is to achieve a mirror-like finish, improving the visual appeal and corrosion resistance of the part. Surface polishing gives the gear box cover a professional and flawless appearance.

CNC Machining and Tapping:

In order to ensure the gear box cover fits seamlessly into the transmission system, CNC machining and tapping are performed. CNC machining involves removing any excess material and refining critical dimensions to achieve the desired specifications. Tapping involves creating threads in the casting that allow for easy installation and connection with other components. These steps guarantee the compatibility and functionality of the gear box cover.

The production of high precision aluminum die casting parts is a meticulous journey that combines various manufacturing processes. From the initial casting to the different stages of finishing, such as trimming, deburring, shot blasting, surface polishing, CNC machining, and tapping, every step contributes to creating a high-quality gear box cover for transmission systems. Ultimately, these parts play a crucial role in ensuring the smooth operation of mechanical systems, exemplifying the importance of precision engineering in modern industries.

Post time: Aug-14-2023