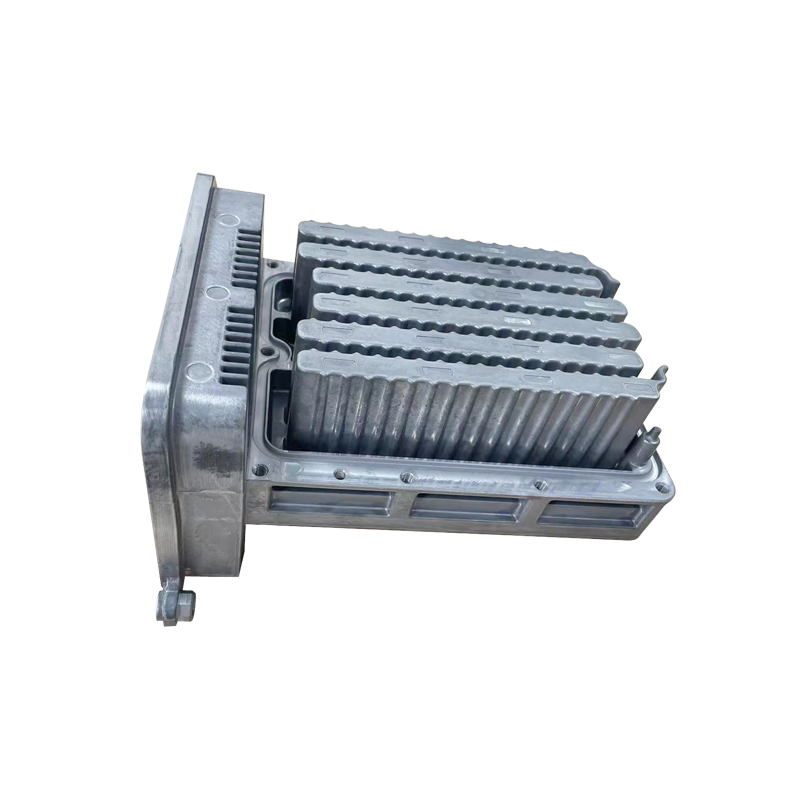

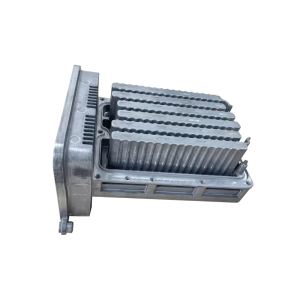

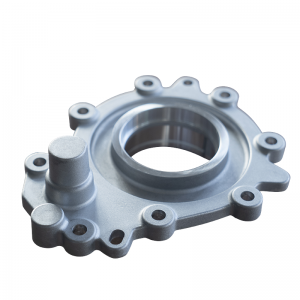

Die Casting Aluminum Housing of PTC used for Electric Vehicle

Product Details

| Processing | Die Casting die and die casting production |

| Trimming | |

| Deburring | |

| Bead blasting/sand blasting/shot blasting | |

| Surface polishing | |

| CNC machining ,tapping ,turning | |

| Degreasing | |

| Inspection for size | |

| Machinery and test equipments | Die casting machine from 450~1650tons |

| CNC Machines 60 sets including brand Brother and LGMazak | |

| Drilling machines 6 sets | |

| Tapping machines 5 sets | |

| Degreasing line | |

| Automatic impregnation line | |

| Air tightness 8sets | |

| Powder coating line | |

| Spectrometer (raw material analysis) | |

| Coordinate-measuring machine (CMM) | |

| X-RAY ray machine to test air hole or porosity | |

| Roughness tester | |

| altimeter | |

| Salt spray test | |

| Application | Aluminum cast pump housings,motor cases, battery cases of electric vehicles, aluminum covers ,gearbox housings etc. |

| Applied file format | Pro/E, Auto CAD ,UG, Solid work |

| Lead time | 35-60 days for mold , 15-30 days for production |

| Main export market | Western Europe ,Eastern Europe |

| Company advantage | 1) ISO 9001, IATF16949,ISO14000 |

| 2) Owned die casting and powder coating workshops | |

| 3) Advanced equipment and excellent R&D Team | |

| 4) Highly skilled manufacturing process | |

| 5) A broad variety of ODM&OEM product range | |

| 6) Strict quality Control System |

Aluminum Casting Design Best Practices: Design for Manufacturing(DFM)

9 Aluminum Die Casting Design Considerations to Keep in Mind:

1. Parting line

2. Shrinkage

3. Draft

4. Wall Thickness

5. Fillets and Radii

6. Bosses

7. Ribs

8. Undercuts

9. Holes and Windows

FAQ

Q: When did your company start to manufacture the products?

A: We started from the year of 2011.

Q: May I get a free sample?

A: 3~5pcs T1 samples are free , the more quantity parts need to be paid.

Q:What is your Minimum order?

A: Due to our specialty in short run orders, we are very flexible in order quantities.

The MOQ we can accept 100-500pcs /order as trial production ,and will charge setup cost for small volume production .

Q: What is the lead-time of mold and production?

A: Mold 35-60 days ,production 15-30 days

Q: What is your payment terms?

A: We accept T/T .

Q: What certification do you have?

A: We have got ISO and IATF certification .

Our factory view

We have full services except above processing ,we do the surface treatment in house including sandblasting ,chorme plating ,powder coating etc . our goal is to be your preferred partner , welcome to send us the inquiry at info@kingruncastings.com