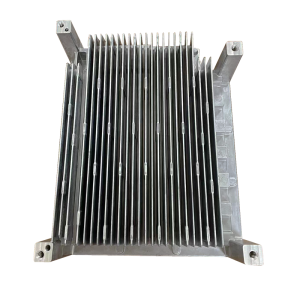

Die cast aluminum heat sink housing/heat sink cover

Die casting is a highly efficient manufacturing process that can produce parts with complex shapes. With die casting, heat sink fins can be incorporated into a frame, housing or enclosure, so heat can be transferred directly from the source to the environment without additional resistance. When used to its full potential, die casting provides not only excellent thermal performance, but also significant savings in cost.

Advantage of Die Cast Heatsink

The advantages or disadvantages of a die-cast heat sink depending on the type of materials from which it is manufactured. For example, aluminum is the most used material to produce die-cast heat sinks. Some major advantages of die-cast heat sinks are listed below:

1.First of all, you should notice that die-cast heat sinks work more efficiently for electrical devices.

2.Die cast heat sinks involve the casting process, hence, they can exist in large varieties.

3.Fins of die-cast heat sinks may exist in different spaces, shapes, and sizes.

4.There are reduced complexities in die-cast heat sink designs. As a result, there is a reduced need to perform machining.

5.You can add different channels to dissipate heat from the die-cast heat sink.

6.Die cast heat sinks are cheaper and can be sold in large volumes.

7.You can have multiple product orientations in die-cast heat sinks. No matter what the orientation of components is, heat flow is maintained properly.

8.Manufacturers can also customize die-cast heat sinks according to your requirements.

Table of Contents

Aluminum Casting Design Best Practices: Design for Manufacturing(DFM)

9 Aluminum Die Casting Design Considerations to Keep in Mind:

1. Parting line 2.Ejector pins 3. Shrinkage 4. Draft 5. Wall Thickness

6. Fillets and Radii 7. Bosses 8. Ribs 9. Undercuts 10. Holes and Windows