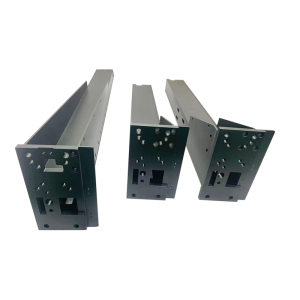

Aluminum Alloy Extrusion

Aluminum alloy extrusion (aluminum extrusion) is a manufacturing process by which aluminum alloy material is forced through a die with a specific cross-sectional profile.

A powerful ram pushes the aluminum through the die and it emerges from the die opening.

When it does, it comes out in the same shape as the die and is pulled out along a runout table.

Extrusion Method

The billet is pushed through a die under high pressure. Two methods are used based on clients’requirements:

1.Direct Extrusion: Direct extrusion is the more traditional form of the process, the billet flows directly through the die, suitable for solid profiles.

2.Indirect Extrusion: The die moves relative to the billet, ideal for complex hollow and se-mi hollow profiles.

Post-Processing on Custom Aluminum Extrusion Parts

1.Post-Processing on Custom Aluminum Extrusion Parts

2.Heat treatments e.g., T5/T6 temper to enhance mechanical properties.

3.Surface treatments to improve corrosion resistance: Anodizing ,Powder coating.

Applications

Industrial Manufacturing: Heatsinks covers, electronics housings.

Transportation: Automotive crash beams, rail transit components.

Aerospace: High-strength lightweight parts (e.g., 7075 alloy).

Construction: Window/door frames, curtain wall supports.

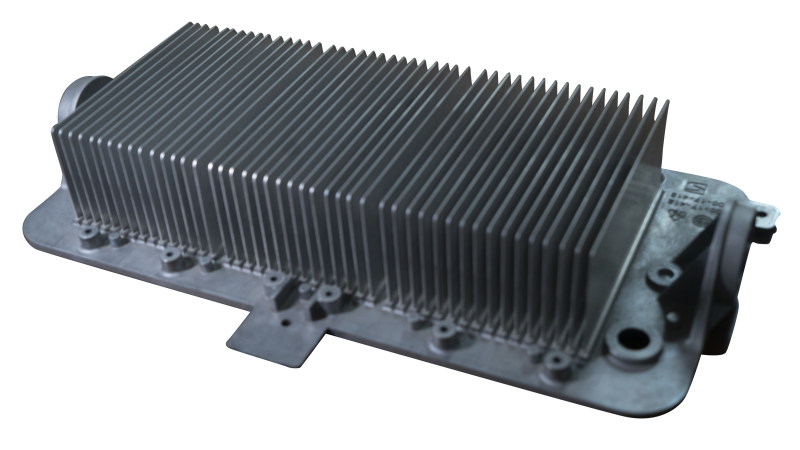

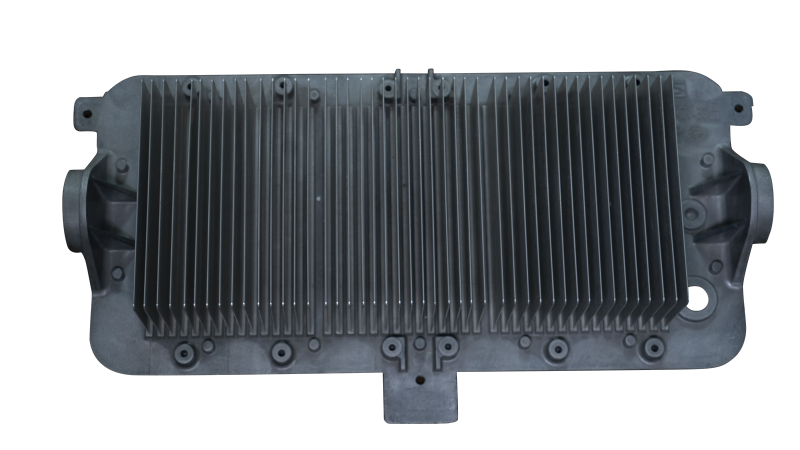

Aluminum Extruded fins+ Aluminum Diecast body

Diecast together with extruded fins