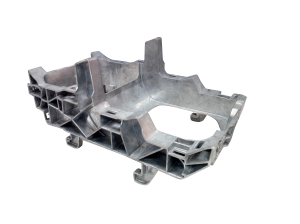

Aluminum die casting samll cable cover of electrical component

Die Casting Process

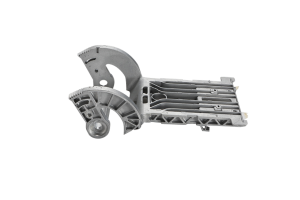

Die casting is a highly efficient manufacturing process that can produce parts with complex shapes. With die casting, heatsink fins can be incorporated into a frame, housing or enclosure, so heat can be transferred directly from the source to the environment without additional resistance. When used to its full potential, die casting provides not only excellent thermal performance, but also significant savings in cost.

Die Casting & Machining

To manufacture the highest-precision aluminum components, Kingrun facilities utilize 10 high-pressure cold chamber die casting machines ranging from 280 tons to 1650 tons in capacity. Secondary operations such as drill tapping, turning, and machining are performed in our shop. Parts can be powder coated, bead blasted, deburred, or degreasing.

Die Casting Feature

Aluminum Casting Design Best Practices: Design for Manufacturing(DFM)

9 Aluminum Die Casting Design Considerations to Keep in Mind:

1. Parting line 2.Ejector pins 3. Shrinkage 4. Draft 5. Wall Thickness

6. Fillets and Radii 7. Bosses 8. Ribs 9. Undercuts 10. Holes and Windows