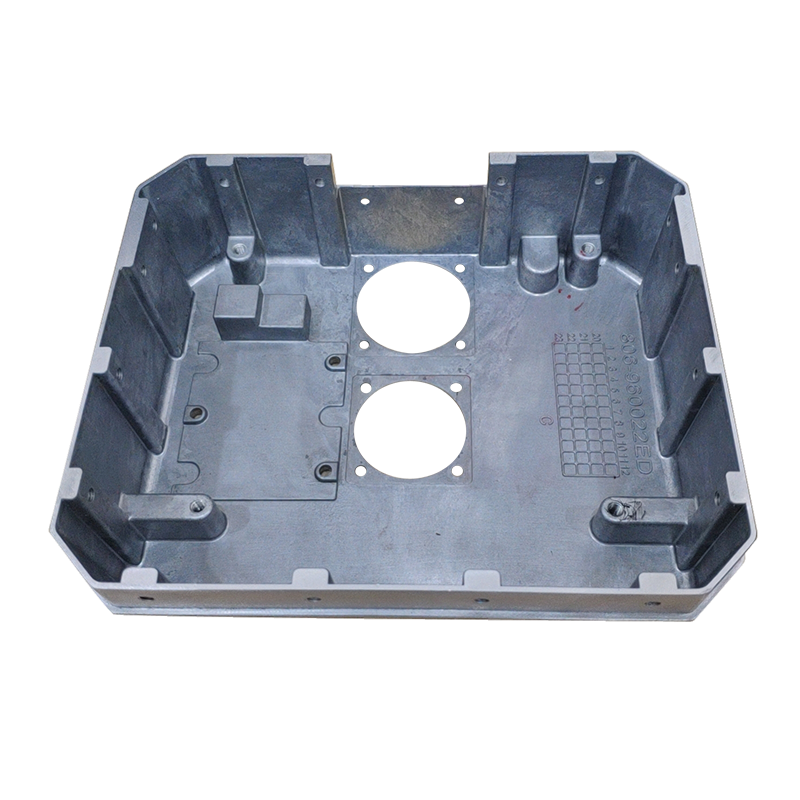

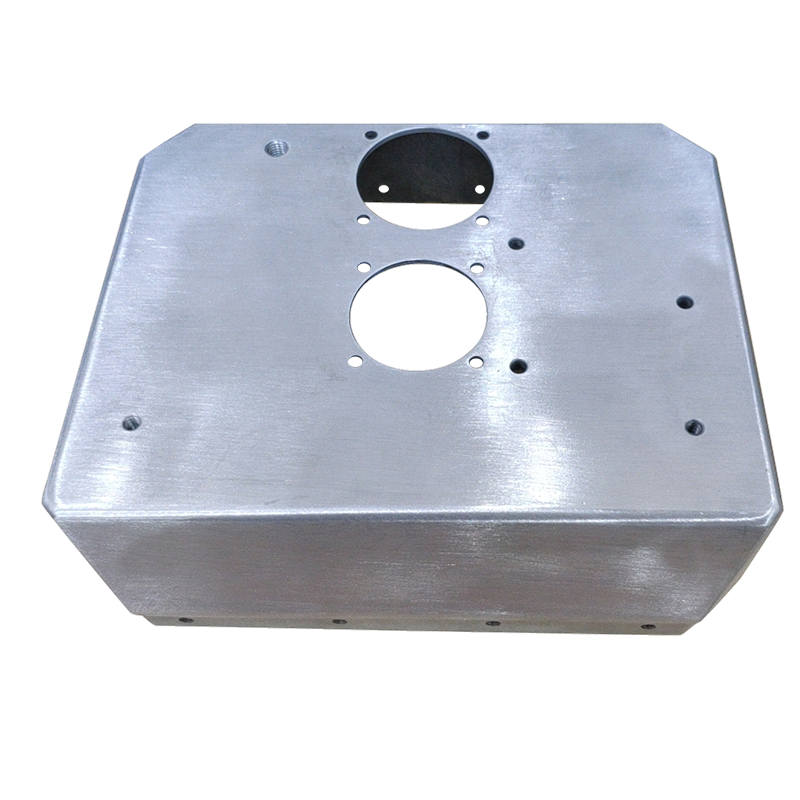

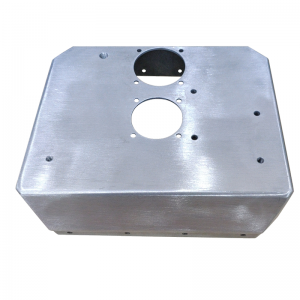

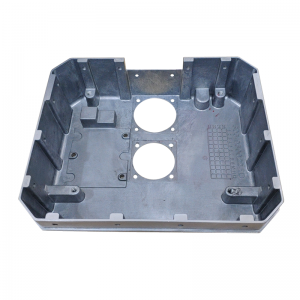

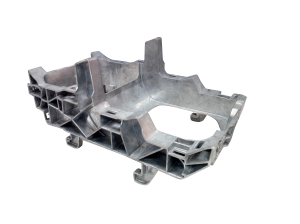

Aluminum casting rear cover of electrical box

Specifications

Kingrun Technology is your complete casting source. Our services include :

Mold design and manufacturing

Aluminum die casting from 0.5kg to 8kg ,max size 1000*800*500mm

Casting finishing using state-of-the art CNC machining

Surface treatment including deburring ,polishing ,conversation coating ,powder coating etc.

Assembly and package : Carton ,pallet ,box ,wooden cases etc. customized according to customers’requirements.

Kingrun projects cover a broad and diverse range, including:

5G Telecommunications products

Consumer electronics

Automotive components

Lighting

Design and Simulation tools

● PRO-E, Solid Works,UG or translators as needed.

● Casting Design Consulting.

● Flow3D, Castflow, for flow and thermal simulation.

● Prototyping in soft molds or alternative casting processes.

● Gating analysis and design for optimal flow and properties

● Internal Review process for design decisions and planning.

● Alloy selection to match property requirements.

● Design coupled to part property requirements.

Finished Product Inspection

Check dimension by calipers, height gauge & CMM

100% thermal test by automatic thermal test line to ensure performance

Visual inspection is performed to verify that there are no cosmetic defects

FAI, RoHS & SGS is always provided to customer

Die Casting Process FAQs

What is cold chamber die casting?

Cold chamber refers to the relative temperature of the injection mechanism. In the cold chamber process metal is melted in an external furnace and transported to the injection mechanism when the machine is ready to make a casting. Because the metal needs to be transferred to the injection mechanism production rates are typically lower than the hot chamber process. Aluminum, copper, some magnesium, and high aluminum content zinc alloys are produced using the cold chamber die casting process.

What are good design practices for die cast parts ?

• Wall Thickness – Die castings benefit from a uniform wall thickness.

• Draft – Sufficient draft is required to extract the casting from the die.

• Fillets – All edges and corners should have a fillet/radius.