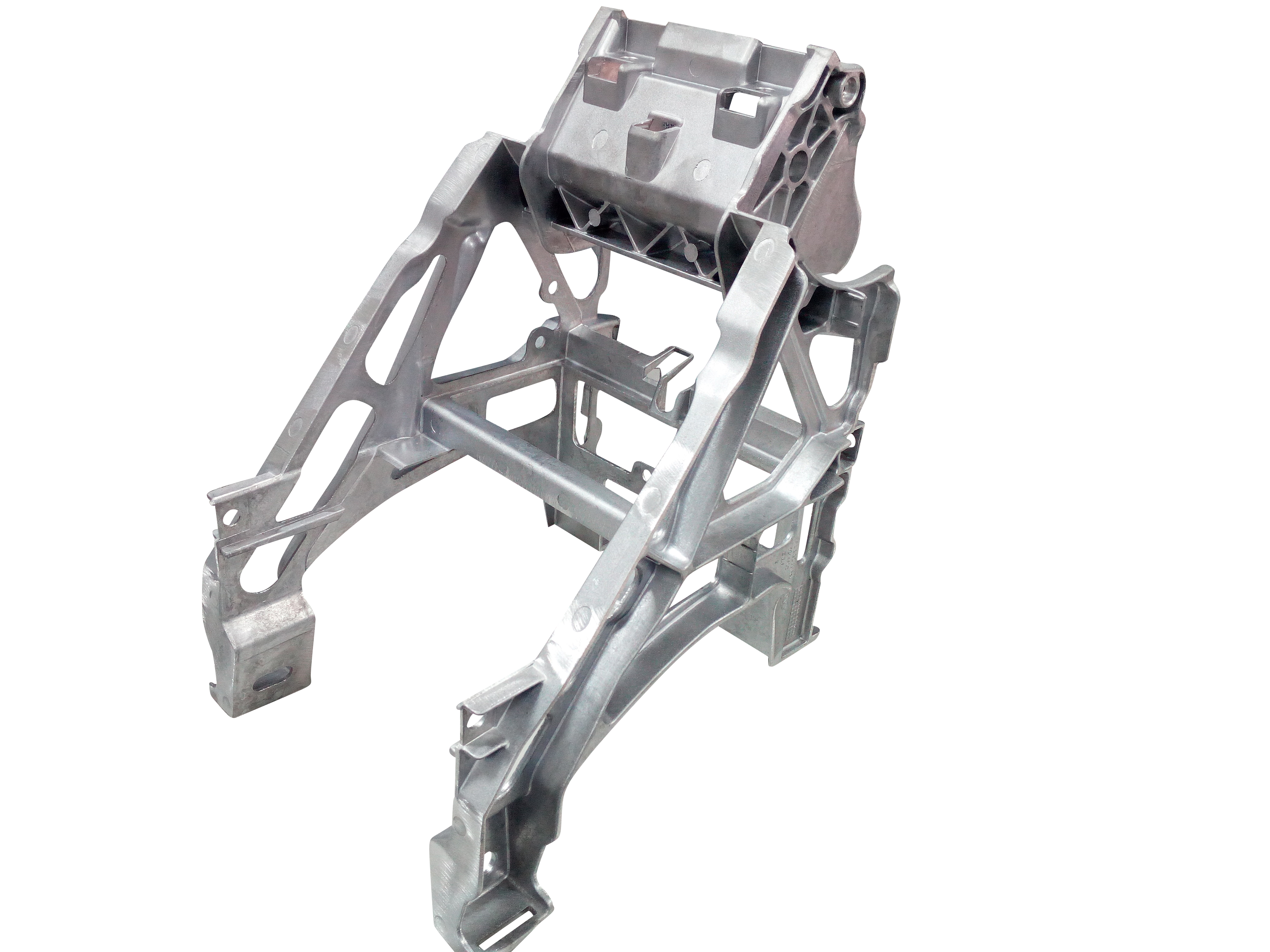

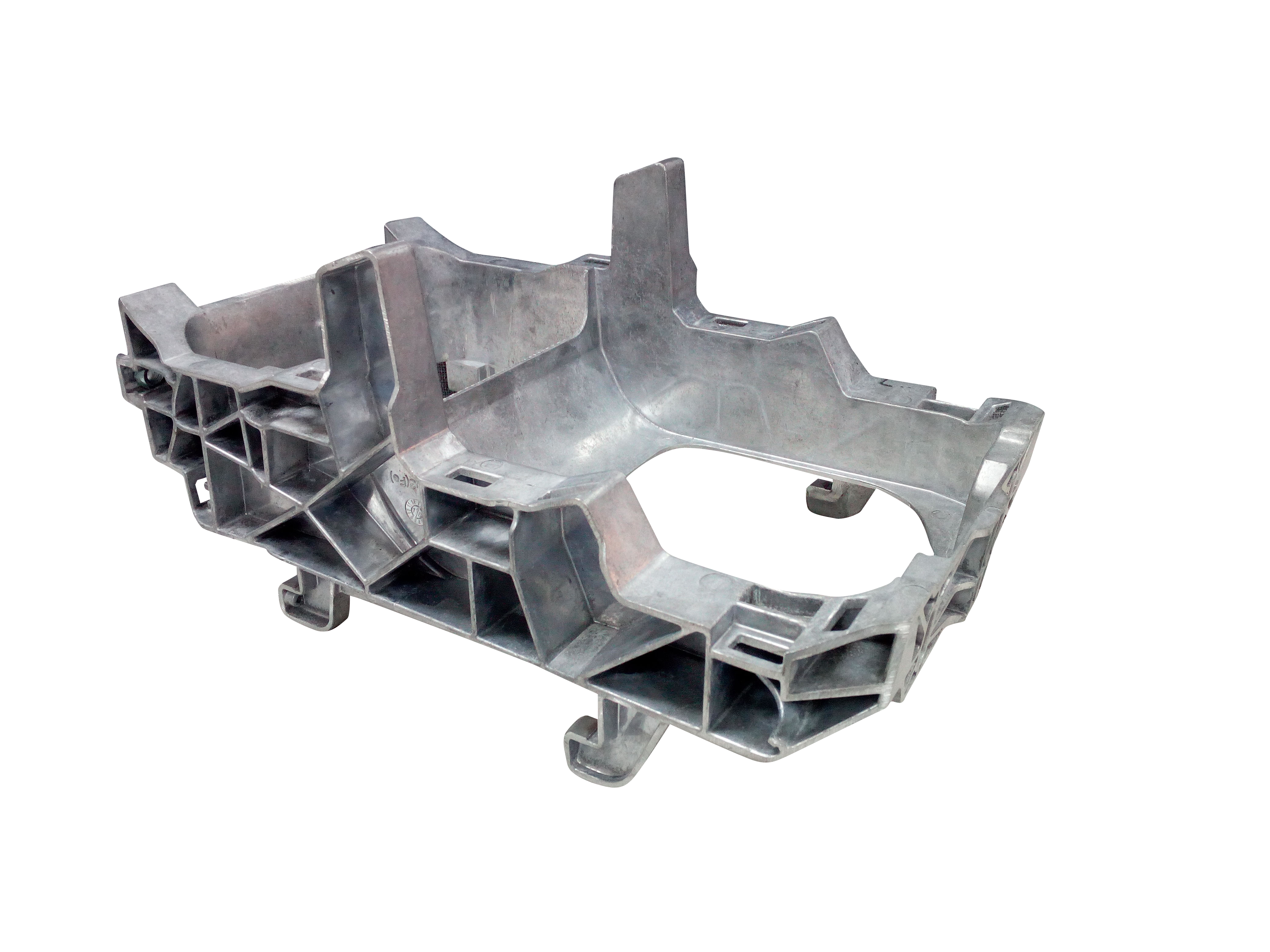

Aluminum casting armrest bracket with high quality-car seat component

Product Details

|

Processing |

High Pressure Die Casting Trimming Deburring Shot blasting Surface polishing CNC machining ,tapping ,turning Bead blasting Inspection for size |

|

Machinery |

Die casting machine from 450~1650tons CNC Machines 60 sets including brand Brother and LGMazak Drilling machines 6 sets Tapping machines 5 sets Degreasing line Automatic impregnation line Air tightness 8sets Powder coating line Spectrometer (raw material analysis) Coordinate-measuring machine (CMM) X-RAY ray machine to test air hole or porosity Roughness tester altimeter Salt spray test |

|

Other auto parts we can do |

Aluminum housings ,motor cases, battery cases of electric vehicles, aluminum covers ,gearbox housings etc. |

|

Tolerance grade |

ISO 2768 |

|

Mold life |

80,000 shots/mold |

|

Lead time |

35-60 days for mold , 15-30 days for production |

|

Main export market |

Western Europe ,Eastern Europe |

|

Packing and Shipping |

Standard export package: bubble bag +carton+ pallet ,as per customers’ request to meet the needs. Accept EXW ,FOB Shenzhen ,FOB Hongkong , Door to Door (DDU)

|

Benefits of Aluminum Die Casting

The process of aluminum die casting is a highly reliable, economically sound, and extremely efficient method of producing durable and sturdy parts. Once a die is cast, it can be reused innumerable times in the production of thousands of identical parts without flaws or deformities. Intricate and specialized designs can easily be produced in huge quantities requiring little to no machining or finishing, which limits labor and handling costs.

A benefit of aluminum die casting is its ability to take unusual and geometrically challenging designs and reproduce them flawlessly. There are instances where a part may have delicate features that include unique angles and thin walls somewhat similar to plastic injection molds. Aluminum die casting offers the same types of functions as plastic molds but produces far stronger and more resilient parts. Regardless of the specifications, die casting can recreate the same types of parts as plastic injection molds with the added benefit of a final product that is stronger, lighter, and with dimensional precision.

One of the problems related to part production is the need to polish, machine, and complete special handling of the final product. Parts produced by die casting come out of the die in perfect condition and require very little handling other than to be packed and prepared for shipment. Finished parts are smooth and durable able to withstand many years of wear.

Welcome to send us your email at info@kingruncastings.com to provide us with more information on your projects as well as your requirements and timeline. We will review your request and send you quotation asap .

Our factory view