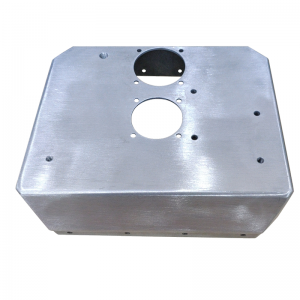

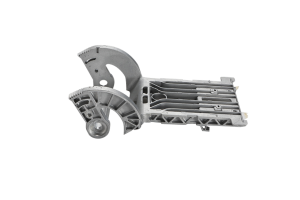

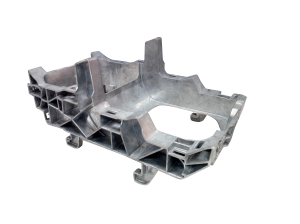

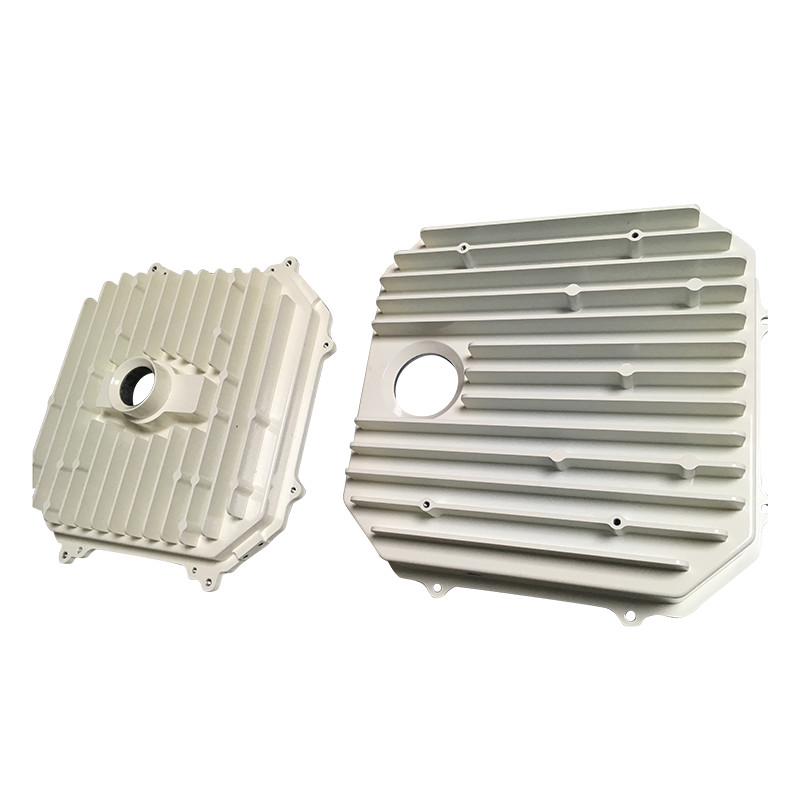

Aluminum casting base and cover for 5G outdoor microwave radio product

The ability of production process

Die casting

Trimming

Deburring

Shot blasting

Surface polishing

Chrome plating

Powder painting

CNC tapping & machining &turning

Helical insert

Screen printing

Our Advantage

1. A group with 25 years experience in engineering and manufacturing.

2. Passed IATF 16949/ISO 9001

3. Good quality control

4. 100% QC Inspection

5. With samples and order: We can offer dimension report, Chemical composition and Other related report of process control .

6. Near Hongkong Port and Shenzhen Port

Quality Control

The precision die casting process is very complicated. It requires a lot of quality management controls from beginning to avoid internal and surface defects or tolerance problem. Our quality management controls includes Control Plan, Process Flowchart, Process Failure Mode & Effects Analysis, First Article Inspection, First-Piece Inspection, In-Process Inspection, In Process Visual Inspection, Last Piece Inspection and Final Audit.

Die Casting Benefits for parts of Telecommunications:

When designing your next Telecommunications connectors or devices, consider die casting as your process of choice. When you partner with Kingrun you can receive the following benefits from our die casting processes:

● Complex net shapes

● Consistent quality over high volumes

● Cost-effective, high-volume production

● Tight tolerances achieved as cast

● Cast housings are extremely durable

● Integration of heat sinks within product design

● Fully recyclable for achieving stricter product legislation

● Wide variety of finishes from high-specification plating to cosmetic finishes

● Value engineering achieves cost savings

● Minimal draft angles on internal features

● Proprietary thin-wall Aluminum technology for telecommunications devices.